“Electrical Model of a Membraneless Micro Redox Flow Battery - Fluid Dynamics Influence”

“Adaptive Microfluidic Modeling of a Membraneless Micro Redox Flow Battery Using Extended Kalman Filter”

“Preconditioning Operation of Membraneless Vanadium Micro Redox Flow Batteries”

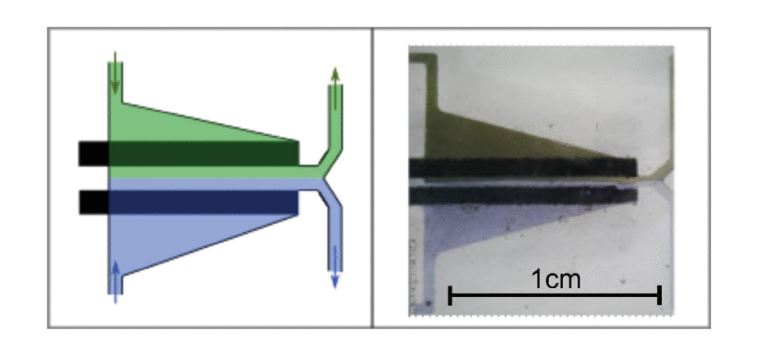

“Deflection and control of the mixing region in membraneless vanadium micro redox flow batteries: Modeling and experimental validation”

“Membraneless Micro Redox Flow Battery: From Vanadium to Alkaline Quinone”

“Electrical Model of a Membraneless Micro Redox Flow Battery - Fluid Dynamics Influence”

“Electrical Model of a Membraneless Micro Redox Flow Battery – Fluid Dynamics Influence” by Bernaldo de Quirós et al (http://dx.doi.org/10.1109/ACCESS.2023.3273927 , 2023)

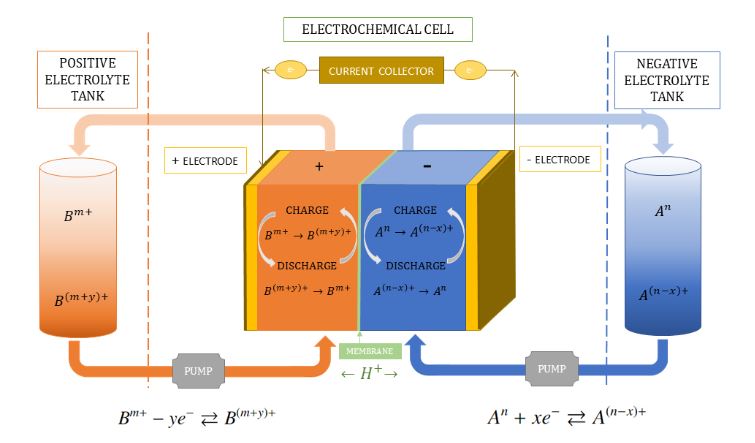

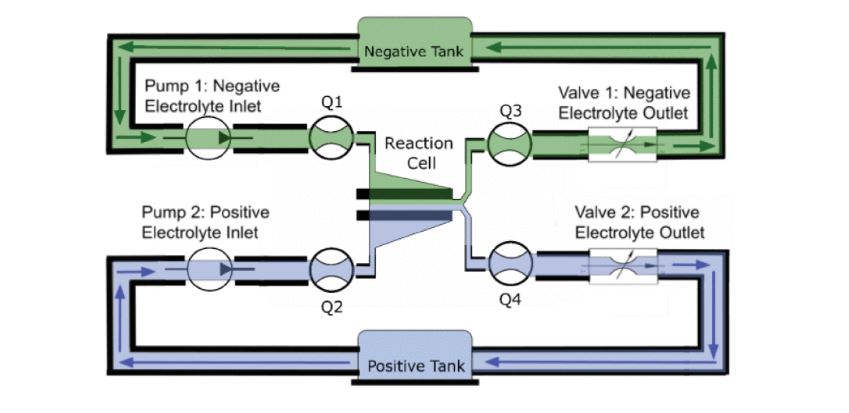

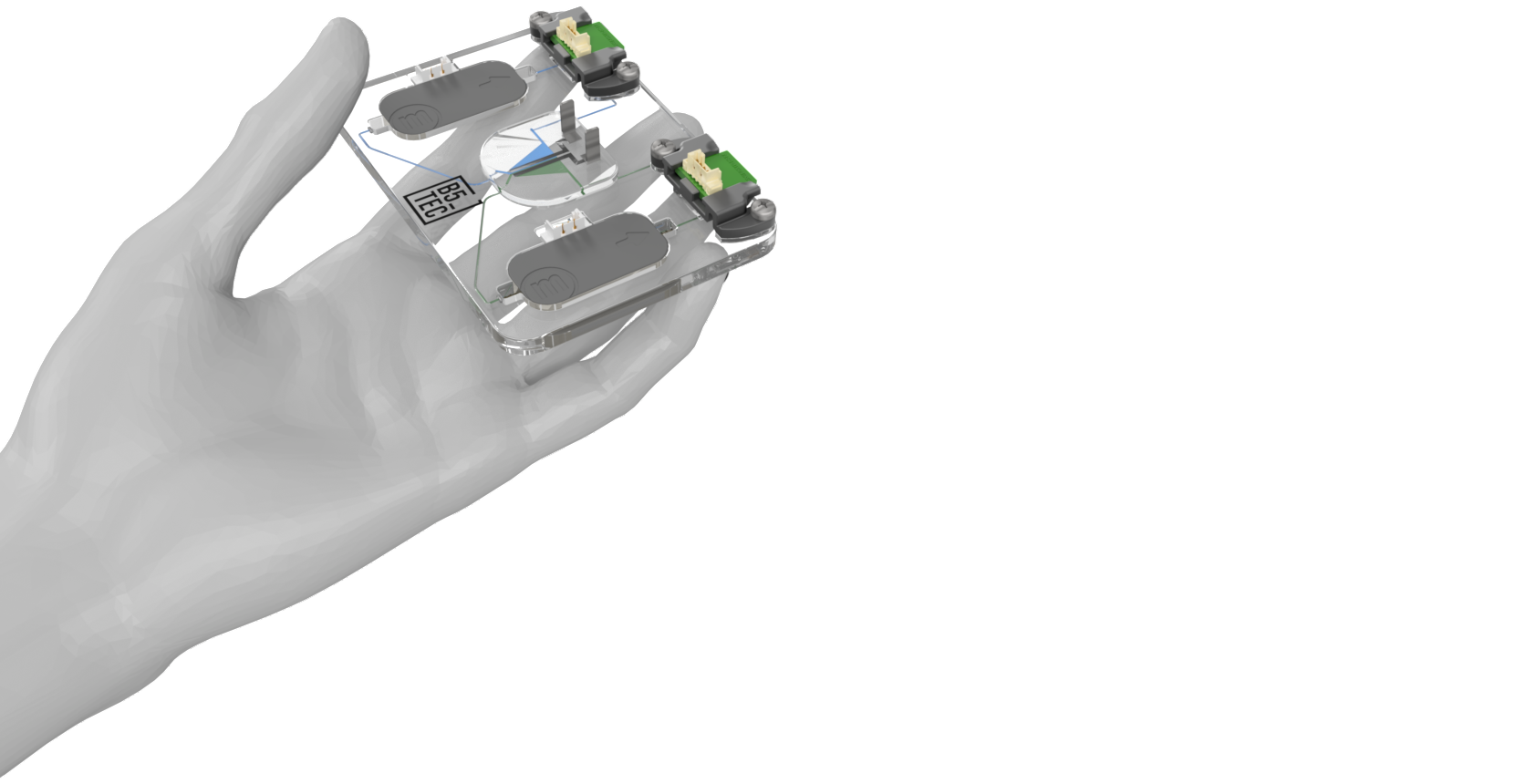

This work enhances the incorporation of the influence of microfluidic dynamics in the electrical response of membraneless micro redox flow batteries (mmRFBs) by introducing a modified equivalent electrical circuit with fluid dynamics parameters. The proposed models are validated with experimental data, showing accurate descriptions of the interplay between fluid dynamics and electrical response. This work provides relevant tools that push ahead in operation optimization for mmRFB, and the setup, including flow controllers and microvalves, has been crucial for this research advancement.

“Adaptive Microfluidic Modeling of a Membraneless Micro Redox Flow Battery Using Extended Kalman Filter”

“Adaptive Microfluidic Modeling of a Membraneless Micro Redox Flow Battery Using Extended Kalman Filter” by Bernaldo de Quirós et al. (http://dx.doi.org/10.1109/ACCESS.2023.3313416 , 2023)

This article presents and validates an adaptative microfluidic model for the operation of a membraneless micro redox flow batteries (mmRFBs) . The model is developed with dynamic equations, real-time correction factors using a Kalmar-filter and careful instrumentation, that integrates the flow controller and the microvalves. Based on the presented model and the setup, for the first time, a closed loop control is implemented on a mmRFB. The implementation is validated through simulations and experiments, demonstrating pioneering advances in closed-loop optimization and adaptative microfluidic modeling. The setup used in this work has been crucial in obtaining the results presented in the article, since the instrumentation allows for high accuracy in the operation and control of fluids and their interfaces.

“Preconditioning Operation of Membraneless Vanadium Micro Redox Flow Batteries”

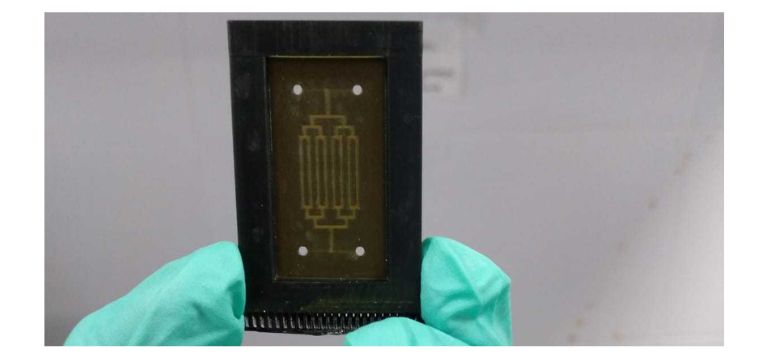

“Preconditioning Operation of Membraneless Vanadium Micro Redox Flow Batteries” by Oraá-Poblete et al. (https://doi.org/10.1002/batt.202300367 , 2023)”

This article presents a novel strategy for preconditioning operation in a membraneless vanadium micro redox flow batteries (mvmRFB) with automated closed-loop control. It lays the groundwork for successful charge-discharge cycling in mvmRFB. To do so, the preconditioning process is carefully studied, enhancing the importance of optimizing the flow rate ratio, the effects of low internal resistance and emphasizing the necessity of real-time monitoring of electrolyte concentrations to prevent charge imbalance. To implement the preconditioning process described, the instrumentation and hydraulic setup used has been crucial. The use of a flow controller and microvalves has been essential for the optimization of the preconditioning operation process.

“Deflection and control of the mixing region in membraneless vanadium micro redox flow batteries: Modeling and experimental validation”

“Deflection and control of the mixing region in membraneless vanadium micro redox flow batteries: Modeling and experimental validation” by de las Heras et al. (https://doi.org/10.1016/j.ijheatmasstransfer.2024.125921 , 2024)”

This article presents a new control system method that implements the PDF, the flow controller and the microvalve. With the suggested setup the article demonstrates the mitigation of undesired disturbances in the hydraulic circuit, thereby minimizing crossover losses. This work sets an important precedent in microfluidic device research by achieving a feasible control method that goes beyond anything previously suggested in literature. All this has been possible thanks to the use of B5tec’s devices.

“Membraneless Micro Redox Flow Battery: From Vanadium to Alkaline Quinone”

“Membraneless Micro Redox Flow Battery: From Vanadium to Alkaline Quinone” by Torres et al. (https://doi.org/10.1002/batt.202400331 , 2024)”

This article presents the first proof-of-concept of a membraneless micro redox flow battery (MRFB) with automated closed-loop control, successfully achieving charge-discharge cycling using both vanadium and alkaline quinone electrolytes. The setup used to achieve this groundbreaking advance in mmRFB development incorporates B5tec’s flow controller and microvalves. The high precision of these devices has allowed to obtain the highest energy efficiency reported for such systems up to date, with the alkaline quinone version reaching 28.9% efficiency.