Energy Storage Solutions

MICRO FUEL CELL

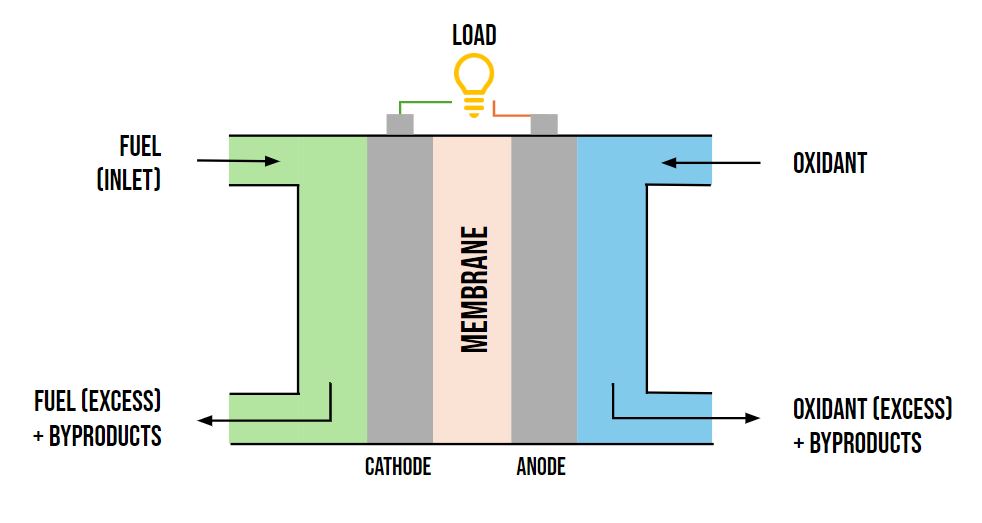

A fuel cell is an electrochemical cell that transforms the chemical energy of a fuel (often alcohols or hydrogen) and an oxidizing agent (often oxygen or air) into electricity through a pair of redox reactions. The reactions are controlled through cell voltage, discharging the fuel and generating power, while byproducts are discarded. These devices are not rechargeable, as fuel is consumed. At B5tec, the main fuel cell in development is a Methanol Cell for stationary applications. Methanol is used given its high theoretical energy density.

Why micro fuel cells?

When sustainable fuels are used, fuel cells are an interesting alternative to traditional rechargeable batteries. As a result, fuel cells are being developed at all scales. The development of micro fuel cells has generated interest in the industry, given its great potential. Some of the advantages of scaling down fuel cells into microscale are:

The reduction of the electric pathway lowers the internal resistance of the cell.

An increased surface-to-volume ratio results in a reduction of the size of the stack, generating more compact systems.

At the micro scale, flow distribution is better optimized and controlled, generating larger power densities.

Material usage and costs can be reduced due to a more efficient performance, and possibly avoiding the use of ionomeric membranes.

It could also be found that with a better surface volume ratio, a higher usage of the catalyst is achieved, which is usually the most expensive component of the system. Resulting in further cost reduction.

What are the challenges?

However, to achieve the mentioned advantages, some challenges need to be addressed.

Micro fuel cell performance is very sensitive to assembly and manufacturing tolerances. Accurate microfabrication is critical to obtain reliable and repeatable results. As a result, the ability to implement very precise manufacturing processes is key to an efficient micro fuel cell.

As in all microfluidic devices, flow management is critical for adequate functioning. In the case of fuel cells, the challenge is more critical due to the presence of multiphasic flows. As the fuel and the oxidant react, gas is converted into liquid, liquid is converted into gas and bubbles appear. Microfluidic systems are more sensitive than larger scale systems to noise and irregularities in the circuits. As a result, all the sensors and actuators need to be able to manage multiphasic flows. To do so, smart reactor and hydraulic system design is needed to facilitate the evacuation of bubbles. The integration of accurate pressure sensors can also help to identify the presence of bubbles and help eliminate them from the reactor with pulsated flow actuated by the flow controller. Overall integration of accurately microfabricated components, precise sensors and coupled actuators to the input of the sensors, is key to a successful implementation of a micro fuel cell.

Furthermore, for a membraneless fuel cell, extremely precise microvalves would be needed to control the interface between fuel and oxidizer. These valves, when distributed throughout the hydraulic system, can also help to uniformly distribute the flow and better manage its multiphasic character.

Real-life example:

To solve all the explained challenges, at B5tec we have implemented a micro fuel cell using our own flow controller, pressure sensors and microvalves. Furthermore, we have used our expertise in micromanufacturing to design a specific reactor that complies with the needs of this application field. The micro fuel cell is another example of successful implementation of efficient microfluidic devices using B5tec’s high-precision sensors and actuators.